When it comes to good purchasing practices, reducing audit fatigue is a no-brainer for manufacturers

Strengthening the manufacturer voice in the debate on better buying behavior would embed audit harmonization as a key factor in healthy supply chain relations.

Improving purchasing practices is high on the sustainability agenda, particularly as the global pandemic shone a light on the severe power imbalance between buyers and suppliers. In parallel, there is growing recognition that reducing the audit burden on manufacturers is a good purchasing practice. Despite calls from manufacturers for greater audit harmonization, reducing audit fatigue is often overlooked in MSI-driven guidance on improving purchasing practices. This highlights the importance of including manufacturers in efforts to define good buying behavior, so that the issues that impact them are not overlooked.

Building the case for reducing audit fatigue

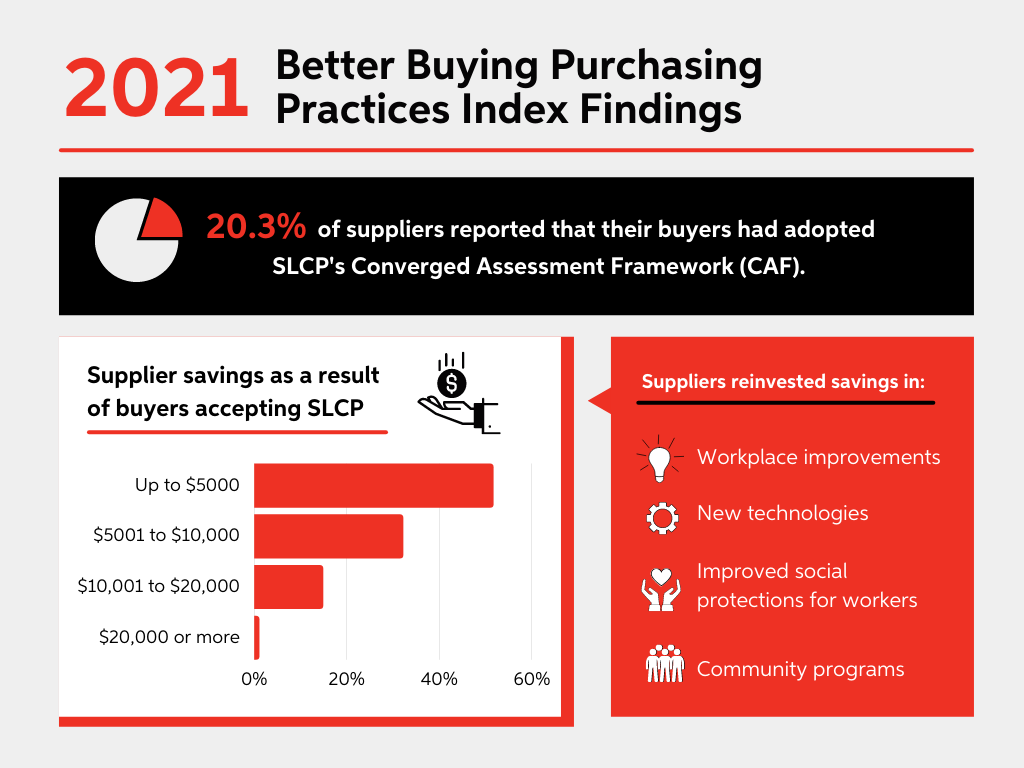

The Better Buying Institute™ (BBI) includes questions on audit harmonization, and specifically on SLCP adoption, in their Better Buying Purchasing Practices Index (BBPPI). In 2021, 20% of suppliers who provided ratings in relation to win-win sustainable partnerships reported that their buyers had adopted SLCP’s Converged Assessment Framework (CAF). These suppliers reported savings of thousands of dollars, in some cases as high as $20,000 a year, which were typically being reinvested in workplace improvements, new technologies, improved social protections for workers, and community programs. Further data on SLCP adoption and associated savings will be gathered this year: the BBPPI 2022 launched on 1 April.

Additional proof that reducing audits benefits suppliers – and ultimately workers – is seen in feedback from SLCP signatory manufacturers. Companies such as Shahi Exports in India and Tapya in Turkey have shared the benefits they have experienced by adopting SLCP. These include significant time saved due to a reduction in the number of audits as well as a quicker onboarding process with new buyers in many cases.

Audit harmonization: A sea change in approach?

A growing number of brands and retailers are ditching their proprietary social audit schemes and adopting harmonized tools such as SLCP. In the 2021 BBPPI ratings cycle, 85.4% of suppliers who provided ratings reported that their customers were now accepting existing audits or assessments of factory working conditions in lieu of asking for new audits.

When it comes specifically to SLCP adoption, so far over 55 companies and organizations have publicly stated their commitment to accept SLCP verified data instead of requesting separate audits. Among them is the Sustainable Apparel Coalition (SAC) which, by choosing to fully adopt SLCP’s Converged Assessment Framework as the backbone of their Facility Social & Labor Module (FSLM), is signaling their firm commitment to converged tools to drive supply chain impact.

Prioritizing audit reduction: Ensuring the voice of manufacturers is heard

In recent months various MSIs have published principles, guidelines, and metrics to improve purchasing practices. While increasing focus on this topic is welcome, such initiatives will only be effective if manufacturers are considered a key stakeholder in the process of defining healthy buyer-supplier relations. In many instances, it seems their voices are currently not being heard in the debate. For example, the reduction of audit duplication is often notably absent from the lists of recommended responsible buying practices, despite the clear benefits of audit harmonization for manufacturers. In contrast, this issue is high on the agenda for manufacturer driven initiatives in this sphere. The Sustainable Terms of Trade Initiative (STTI) includes “Buyers actively work to reduce audit and standard fatigue” as one of the further recommendations for improvement in its 2021 White Paper on the Definition and Application of Commercial Compliance. A separate manufacturer-driven initiative, the Standard Convergence Initiative (SCI), is also working to reduce audit fatigue by measuring the preparedness of standards to converge. It is essential that the issues raised by manufacturers are reflected in the goals and standards that the industry sets for itself on purchasing practices.

“Improvement of purchasing practices is a complex topic, but reduction of audit and standard fatigue is a relatively easy component. So many more manufacturers could benefit from less overlapping audits if their clients would just use SLCP verified data. So many could benefit from their clients dropping proprietary codes in favour of third party standard holders.”

Matthijs Crietee, Secretary General of the International Apparel Federation (IAF)

Can initiatives to improve purchasing practices learn from SLCP’s collaborative approach?

To tackle the issue of audit fatigue, SLCP brought together diverse industry stakeholders, ensuring they all had an equal seat at the table. The result was the CAF, a tool that is now beginning to have a real impact on brands and manufacturers alike by unlocking resources currently tied up in auditing. By embracing a similarly inclusive approach, initiatives to improve purchasing practices could ensure new principles and guidelines reflect the real needs of manufacturers and create meaningful change. SLCP would like to see the issue of audit fatigue – an area of key concern for manufacturers – reflected in improved purchasing practices guidelines and frameworks. Recognition among MSIs and their members of the importance of audit reduction would embed audit harmonization as a key factor in improving purchasing practices, making it more difficult for the industry laggards to resist change and cling to their proprietary audits.

The Better Buying Purchasing Practices Index (BBPPI) 2022 Ratings Cycle is open for ratings from 1 April to 31 May 2022. Find more information here.